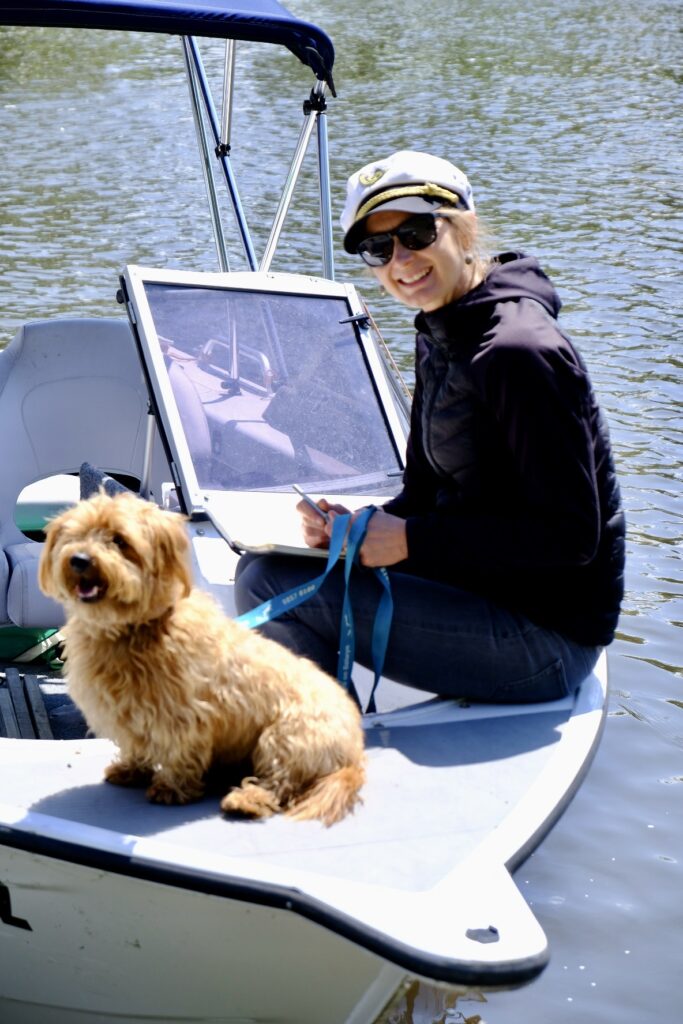

Here is a distillation of an interview with Anthony Despotellis, the Yarra Riverkeeper polystyrene officer. The interview was conducted just before he headed overseas.

Sources and solutions

I first came on borard in March 2020 when I designed Nikki’s report Polystyrene report ‘Polystyrene pollution in the Yarra: Sources and Solutions’. That was the first of a series of reports on polystyrene in the Yarrra The riverkeepers had figured out there was lots of polystyrene in the Yarra and the next step had been to figure out where is was coming from. There are five sources of polystyrene pollution:

- construction,

- white goods,

- loading bays at shopping centres,

- manufacturers, and

- recyclers.

The funding was from the Port Phillip Bay Fund initially and that funding came out of the sale of the Port of Melbourne. We were successful with the first two rounds for our ‘Litter and Flows’ projects. The Victorian government then continued to fund the project from the department, supported by @Faye Spiteri. The work has been referenced in both ‘Yarra/Birrarung and its Parklands’ reports by the Commissioner of Environmental Sustainability and as a priority project in the Birrarung Burndap Birrarung Umako as a priority project. Not bad for a small not-for-profit with limited resources,

Nikki Kowalczyck and the Cleanwater Group

Nikki Kowalczyk ran the first two rounds of the project and in the second round the Cleanwater Group contributed to the development of the methodology based on the work they were doing in Queensland through doing source audits.

I worked on this part of the project with the Cleanwater Group. A lot of the work was done by Cleanwater Group at night monitoring loading bays and manufacturers, and I did the work in the day. I did the in-river estimates and visited 80 residential construction sites.

Challenges with Construction Sites

The challenge with construction sites was that the work went so fast, In two weeks the work on site with the polystyrene was done and over.

Vacuum System

A vacuum system was developed by the Cleanwater Group for vacuuming litter out of the river. This was effective at cleaning up the litter but there was never ongoing funding for this part of the project. It also disturbed the wildlife which was a downside.

Stakeholders

Third part of the polystyrene work was stakeholder related. There was great engagement with government, Melbourne Water and the EPA, ther was some engagement with council, mostly those already doing some work and two main council who were doing good work were Wyndham and Casey. It was hard to find contacts in Council who were interested. I presented to councils three or four times without a lot of response.

Peak building bodies interested only

The response from the building and construction industry was from the peak bodies only. Expanded polystyrene Australia (Beecher Townsend), Master Builders Association and HIA all engaged. No engagement with any builders large or small. Maybe we could have gone harder. MBA said we can’t get members to turn up to these sorts of events. My recollection is that there are 6000 builders with HIA and 6000 with MBA, and 6000 unaffiliated. 18,000 builders in Vic or maybe that is around Australia.

Not my problem

I presented to the the Expanded Polystyrene Australia members at AGM. Two main things came out of that. They didn’t really know where polystyrene was ending up and they didn’t think it was their responsibility. They didn’t see it as a chain of custody issue – if there is polystyrene pollution it is the builder’s fault. There is a code of conduct laid out and, because they have given that guidance to the builders, it is not their problem after that if the builders don’t follow it. Manufacturers have a take-back program but up to the builders to use. Takeback really only for waffler pods not for cladding. I saw one instance of cladding being bagged up. The summary story of it all is: building industry hard to crack. We homed in on EPA and councils’ responsibility

Education only work along side enforcement

Lot of our thinking based on Master Builders Association report done 20 years ago — and education only works if you enforce it as well. So, if this is true then we must make sure enforcement is efficient and effective. For the education to be effective it needs to be back up by meaningful fines. We know that it is technically possible but not done at a good enough rate if at all. The EPA says that once polystyrene leaves the site it can’t be proved that it comes from that site. GED suggests that every builder as responsibly OPAL officers are saying that it is difficult to prove but I thought it was very clear. When I went around there was not much fining going on I could see, not enough to match the amount pollution. The fines are too low to be effective to make change. If the response to polystyrene was strengthened then builders would respond

Roundtables are effective

Roundtables ere effective. Yes definitely first time all those players were gathered together in the one room to talk about this issue. Things uncovered in both round tables that uncovered issues and where we could act. Where the problem is and where we could act.

Polystyrene packaging is being phased out

We talked to whitegoods retailers at the start. Impressed by some. Aldi almost phased out polystyrene from packaging. They are proud of what they are doing. Harvey Norman did not respond to us. Other whitegoods retailers also did not respond. Polystyrene is being phased out in packaging as a general trend.

Polystyrene in construction is expanding

We focussed on construction as nobody doing anything there to reduce polystyrene pollution. It was the largest and toughest nut to crack. Industry polystyrene was to be included in the federal government polystyrene ban but construction lobbied not to have it included as the said they had no alternatives. The was the National Plastics Plan. Polystyrene plates and cups are all getting phased out but industry polystyrene whether B2B or construction is not going to be phased out.

In river is had to tell where the polystyrene has come from as it is so degraded but source audits, construction was number one and whitewoods number two. But pretty close. Difficult material to substitute as it is now so cheap. And hard to replace because of its energy efficiency and therefore high star rating but what is not included in the star rating is the pollution The other issue is the need for housing in a housing crisis and government is saying we need to build faster and cheaper so even less incentive to remove it as it is fast and cheap.

Where to from here?

Where to from here? Enforcement. Polystyrene working group is the number one recommendation. There are talks on who is to lead. Whoever leads needs power and influence. Building industry don’t respond well to small NGO like the Yarra Riverkeeper. We need to keep the work going though. The work is bigger than we can do.

Watch out for our report in October

Our report due in October. The new reports that have built on previous reports. The reports have had a cumulative beneficial effect. This is the first time the recommendations have been critiqued by a round table including all the key players.

0 Comments